MAKE IT FLOW

About us

BESI Marine Systems GmbH is the designer, manufacturer and service provider of FLOW MANAGEMENT SYSTEMS for the marine industry.

Since founding in 1966 the head office is still based in Bremen, Germany. The Production facilities are located exclusively in Germany and Poland. In sales and after-sales support activity and production more than 50 highly skilled employees are working to fulfil our customer requirements.

Our products are proven in more than 6.500 maritime applications!

Represented globally by more than 20 Agents with sales and service facilities BESI Marine Systems GmbH is able to give you a worldwide support.

Tailor-made system design for Tank Management & Valve Control Systems for the marine industry are our speciality – Please feel free to contact us!

Latest News

BESI won contract in India to equip a floating dry dock (FDD) with lifting capacity of 4,000 MT

Together with its Indian partner Marine Electricals (India) Limited BESI Marine Systems GmbH has successfully applied for a mid-sized floating dry…

BESI Marine Systems GmbH celebrates next order for ship series in China

Another success story has been written in Chinese shipbuilding market. Due to BESI’s huge reputation in China and thanks to the tremendous support of…

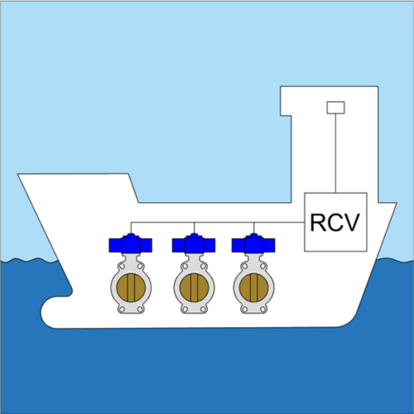

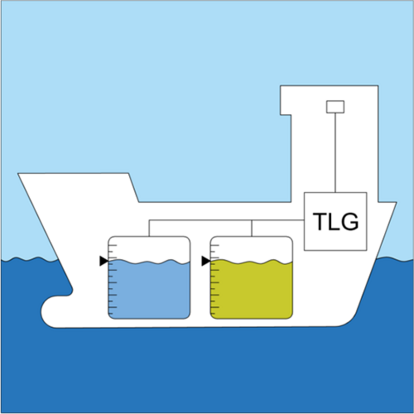

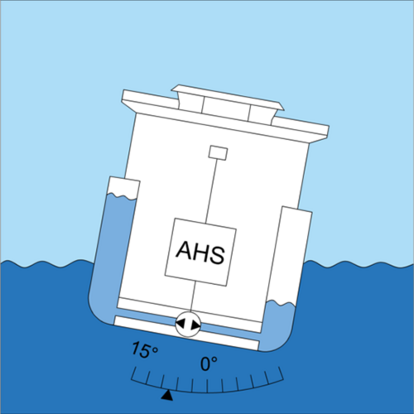

Leading German Shipowner awarded BESI for supplying RCV, TLG and AHS

BESI Marine Systems managed to receive order for four (4) MULTI-PURPOSE VESSELS (MPV) to be built in China, Weihai, Shandong Province. BESI’s scope of…

Systems

Remote Controlled Valves

Tank Level Gauging

Anti-Heeling System

Products

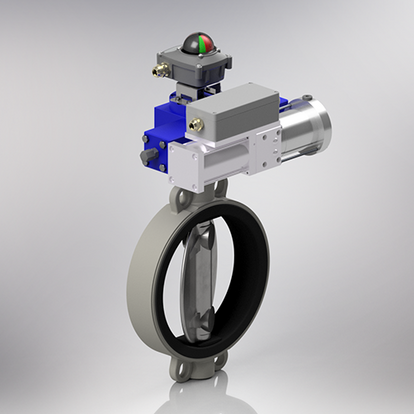

Hydraulic Actuators

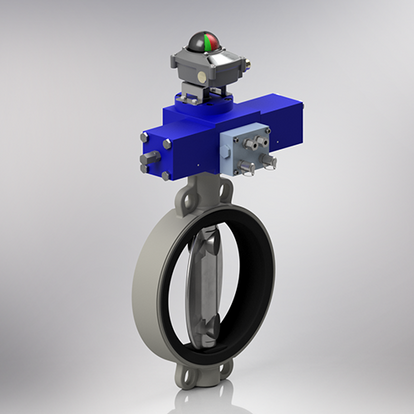

Electro-Hydraulic Actuators

Pneumatic Actuators

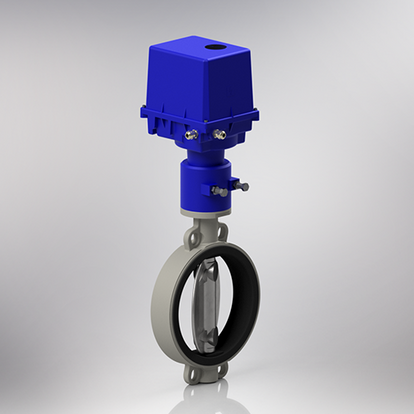

Electrical Actuator

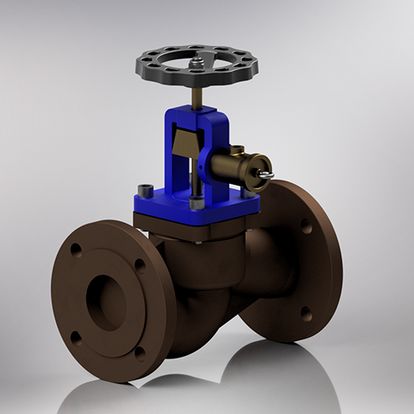

2/3-Way Regulating Valves

Manual Operated Valves

Solutions

Spareparts

Service